NATURAL GAS LIQUIDS CAPTURE & USE

Gas Flaring, CO2 Reduction, Commercialization, Sustainability

SERVICES

NGL Capture & Use

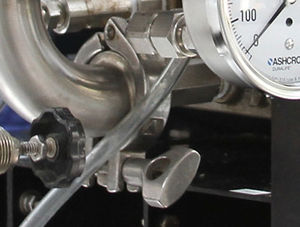

Our patented capture process is housed in a stainless steel chassis described as a Membrane Gas Recovery Unit© (MGRU). Our proprietary membrane elements are encased in stainless steel vessels. These membrane elements are designed to separate and capture Natural Gas Liquids (NGL) from natural gas produced from oil & gas wells during routine operations. The Natural Gas Liquids (NGLs) are retained as valuable Y-Grade commercial resources fit for

a variety of low-carbon sustainable uses.

CO2 Reduction

Capturing up to 90% of Natural Gas Liquids (NGLs) reduces the volume of CO2 emissions gas that would otherwise be flared.

Vaporous NGLs are transformed into liquids by our patented separation and recovery process. Capturing 90% of NGLs may reduce the amount of CO2 emissions up to 55% under certain conditions.

Green Completions

No chemicals and no moving parts are used in our single step process. The capture process begins after the well-completion phase. Our Membrane Gas Recovery Units (MGRU) are hooked up to an oil and water separation device. This device allows natural gas to flow through our MGRU. This practice may be referred to as a “green completion” process under EPA guidelines for reduced emission completions.

Sustainability

We seek to advance environmental and social performance across the energy transition. We seek to bring together all stakeholders to lead in mainstreaming sustainability by advancing climate action, environmental responsibility, and social performance across oil, gas, and renewables activities.

We prescribe to the goals set forth by the International Petroleum Industry Environmental Conservation Association founded by the United Nations in 9174.

ABOUT CLEANSMART

CleanSmart Solutions LLC (CSS) is a membrane technology innovation company. CSS fabricates, installs, and operates US patented Membrane Gas Recovery Units (MGRUs).

WHAT

These Units capture, separate, and reduce CO2 emissions from natural gas liquids (NGLs) that would otherwise be “flared,” i.e., burnt and released into our atmosphere. Flared gas emits polluting emissions that underlie global warming. CSS offers to commercialize this gas and as well as apply its use to multiple low-emission, low-carbon social applications.

Our goal is the reduction of GHG emissions from NGLs toward a low-carbon Net Zero future.

FEATURES

-

Capture up to 90% of the NGLs from a natural gas stream.

-

Reduction of CO2 emissions by up to 55%.

-

No chemicals, no moving parts, no emissions

-

EPA qualification as a “green” completion device.

WHY

The flaring of NGLs roughly equals 2% of all emissions from fossil fuels. Texas and North Dakota account for 80% of flaring in the US. Flaring also occurs on federal and tribal lands throughout the United States.

The World Bank estimates that flaring by 30 countries amounts to 143 billion cubic meters of gas per year. This flaring results in an estimated 400 million tons of CO2-equivalent emissions. In principle, recovery of this gas could provide electricity for all of sub-Saharan Africa.

The World Health Organization notes that almost 2.8 billion people live without electricity, and about 1 billion people use polluting and health damaging biofuels for heating, cooking, and lighting.

CSS offers adaptive technology and economical solutions to overcome challenges and obstacles. Our philosophy is to lead in advanced membrane gas recovery solutions. We also believe in pursuing economic, environmental, and social performance across all stakeholders. We prescribe to best practices designated by International Petroleum Environmental and Conservation Association (IPIECA.org) which was founded the the United Nations in 1974.

MEMBRANE GAS RECOVERY UNIT

Gas Processing Pressure C1, C3++

Single Step - 250 psi

Gas Processing Temperature 125°F/53°C

C3+ Recovery Rate

80% - 90%

Processing Range

1.5mm/scfd - 5.5mm/scfd

Footprint

80’ x 40’ x 8' x 12.2m x 2.4m

Modularity

6 membranes per vessel

20 vessels per Unit

CONTACT

Inquiries

For any inquiries, questions or comments, please call: 415-812-1020 or fill out the following form

Clean Smart Solutions LLC

Contact Us

Exclusive Agent in Egypt

TAQASERVE. LLC

TAQASERVE, LLC

Email: services@taqaserve.com

Headquarters-Egypt:

53 Gamal Abdel Nasser Rd, Victoria, Alexandria

P.O. Box: 28 Al-Saray

Phone : +20 3 358 3209

Fax : +20 3 358 3209

USA Office:

Houston, Texas

P.O. Box 2367, Sugar Land, Texas, 77487-2367

Phone : +1 832 847 2621

Fax : +1 832 944 6659